- Index

- >Projects

- >Projects in progress

- >AEROCONVERTER

AEROCONVERTER Research Project

Innovation in power conversion for the aerospace market

Group : Reliability Engineering and Decision-Making tools

Labelling: none

Duration: 48 months (from January 2024 to December 2027)

Funding: DGAC

Staff involved from LARIS: Bruno CASTANIER, Nicola ESPOSITO, Laurent SAINTIS, Sylvain VERRON

Project partners: See table below

|

Fonction |

Dénomination |

Spécialité |

Commentaires |

|---|---|---|---|

|

Coordinator |

|

Expertise en conception et fabrication de convertisseur de puissance |

Industriel |

|

Partners |

|

Expertise sur la conception et la fabrication de busbars |

Industriel |

|

|

Expertise en fiabilité des composants de puissance |

Laboratoire public de recherche | |

|

|

Expertise en fiabilité des systèmes |

Laboratoire public de recherche | |

|

|

Expertise en Comportement Electromagnétique |

Laboratoire public de recherche | |

|

|

Expertise en Comportement Electromagnétique |

Laboratoire public de recherche | |

|

|

Expertise en analyse de testabilité et de couverture de test |

Industriel | |

|

Sponsor |

|

Donneur d’ordre aéronautique |

Industriel |

Abstract:

The Aeroconverter project is funded by the French Civil Aviation Authority (DGAC), and is led by TRONICO, an expert in power converter design and manufacture, in collaboration with MERSEN, ASTER and the ESEO, IETR, LARIS and SATIE laboratories. The project is sponsored by Airbus Commercial Aircraft, and in particular by the ATA 24 department, which manages the power conversion, distribution and regulation aspects.

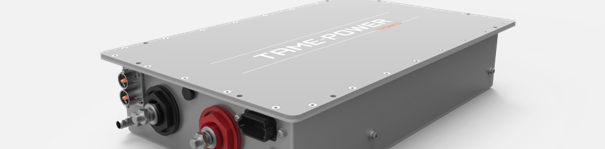

The objectives of the project are to design, manufacture and validate a power converter demonstrator for use in a pressurized zone (use constraints distinct from a non-pressurized zone, more difficult to manage in terms of isolation), integrating several innovations.

The project involves several challenges, including those associated with sub-lot 3.1 Reliability:

- Model and optimize converter reliability using advanced models.

- Predict converter health.

- Implement a production testing strategy that guarantees the reliability performance of the manufactured product.

HVLV power converters are new equipment in the aircraft, so the evolution of their behavior over time represents a challenge to guarantee the safety and availability of the means. This challenge is reflected in a metric: the Mean Time Between Unscheduled Removal (MTBUR). In order to act on the product rather than react to a breakdown, it is useful to monitor the converter's state of health and predict its evolution. Predictive analyses exist today, but not for this type of equipment. It is necessary to consider the product from a dysfunctional point of view, and based on failure analyses and failure mode characterization, to define the measures to be implemented, which will enable us to testify to the converter's state of health. Using these parameters, we will then develop a method for integrating the stress factors influencing converter reliability in the operational context, and the associated uncertainty, to predict a future state of health, enabling maintenance decisions to be made on the equipment. This predictive model will have to be based on the digital twin of the converter's operation, which will have to be produced.

Research activities:

Based on the expressed reliability issues, the main objective is to provide a design for a power converter system enabling an MTBF of 30,000 FH. The aim is also to provide a methodology for demonstrating this objective, which is not dependent on the technology of the power component.

This methodology is based on the development of numerical models which will serve:

(i) as decision-making tools for converter design upstream of the prototyping phase; (ii) as tools for predicting aging by thermal fatigue, and service life throughout the module/power converter duty cycle.

This will involve:

- Characterize and identify reliability drivers at system, board assembly and component levels.

- Determine an architecture to meet the challenges

- Model behavior to predict health at component and system level.

The aim of introducing PHM is to guarantee, and even exceed, operational reliability objectives, taking into account on-line corrective maintenance, expressed in terms of MTBUR (Mean Time Between Unscheduled Removal) and enabling design challenges to be met. This means better management of maintenance interventions based on an estimate of the state of health of the various system components, integrating monitoring of environmental and operational stress factors.

There are a number of issues to be addressed when it comes to PHM:

- From a technological point of view, we need to assess the completeness and quality of existing measurements at system level, and then establish any additional measurements required.

- The design of the PHM subsystem and the collection of complementary measurements will require design choices for measurement sensors, as well as defining, in agreement with the aircraft manufacturer, the integration of the PHM subsystem's on-board intelligence (data storage, transmission and processing, etc.).

- From a scientific point of view, the aim will be to develop a method for integrating the stress factors influencing reliability in an operational context, and the associated uncertainty, based in particular on the digital twin.